Raise the lift arms and install an approved lift arm support device. (See Installing Lift Arm Support Device on Page 10-20-1.)

Stop the engine. Raise the seat bar.

Lift and block the loader. (See LIFTING AND BLOCKING THE LOADER on Page 10-10-1.)

Raise the operator cab. (See Raising The Operator Cab on Page 10-30-1.)

Drain the hydraulic fluid from the reservoir. (See Replacing Hydraulic Fluid on Page 10-120-3.)

Remove the hydraulic fluid reservoir from the loader. (See Housing Removal And Installation on Page 20-70-1.)

Open the rear door of the loader.

Remove the Power Bob-Tach block if so equipped. (See Removal And Installation on Page 20-110-1.)

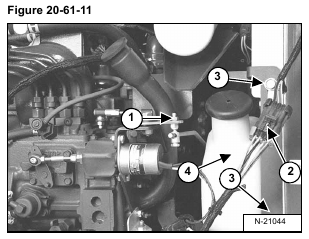

Remove the nut from the speed control linkage (Item 1) [Figure 20-61-11].

Unplug the rear lights electrical connector (Item 2) [Figure 20-61-11].

Remove the belt shield mounting bolts (Item 3) [Figure 20-61-11].

Remove the belt shield.

Remove the coolant recover tank and mount (Item 4) [Figure 20-61-11].

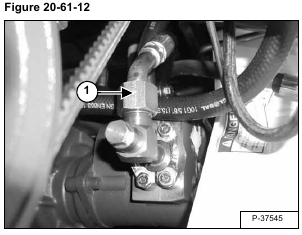

Disconnect and cap the outlet hose (Item 1) [Figure 20-61-12] from the back of the hydraulic pump.

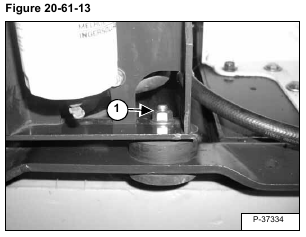

Remove the right rear engine mount (Item 1) [Figure 20-61-13].

Installation: Tighten the engine mount bolt to 70 ft.-lbs. (95 Nm) torque.

Installation: Tighten the engine mount bolt to 70 ft.-lbs. (95 Nm) torque.

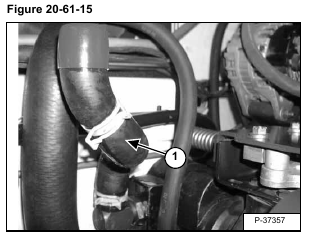

Remove the inlet hose (Item 1) [Figure 20-61-15] from the front of the hydraulic pump.

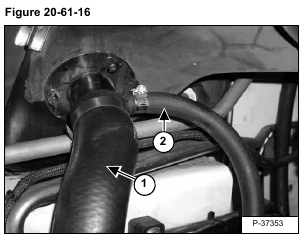

Loosen the hose clamps and remove the fuel fill hose (Item 1) and the fuel vent hose (Item 2) from the loader

[Figure 20-61-16]

Remove the engine speed control rod and the rod guide (Item 1) [Figure 20-61-17].

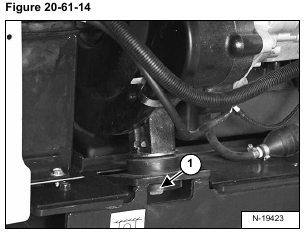

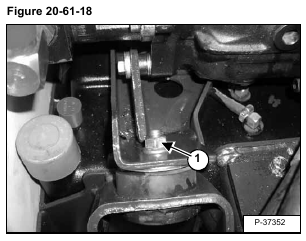

Remove the right front engine mount (Item 1) [Figure 20-61-18].

Installation: Tighten the engine mount bolt to 70 ft.-lbs. (95 Nm) torque.

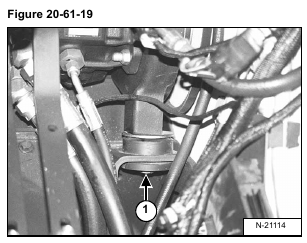

Loosen the left front engine mount (Item 1) [Figure 20-61-19] but do not remove.

Installation: Tighten the engine mount bolt to 70 ft.-lbs. (95 Nm) torque.

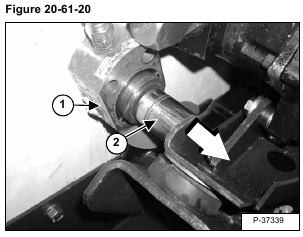

Use a port-a-power (Item 1) [Figure 20-61-20] to push the engine/hydrostatic pump assembly away from the

mainframe.

NOTE: A shaft (Item 2) [Figure 20-61-20] with the dimensions of 1.5” diameter by 2.125” long

will be needed to push the engine/hydrostatic pump assembly.

NOTE: Push the engine/hydrostatic pump assembly only as far as needed to remove the gear pump.

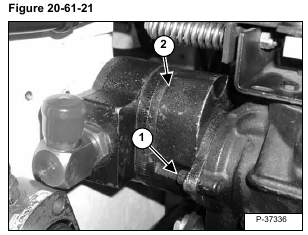

Remove the two mounting bolts (Item 1) [Figure 20-61-21] from the hydraulic pump.

Installation: Tighten the mounting bolts to 27-37 ft.-lbs. (37-50 Nm) torque.

Remove the hydraulic pump (Item 2) [Figure 20-61-21] from the loader.

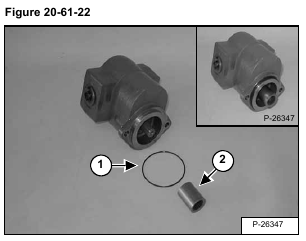

Remove the O-ring (Item 1) [Figure 20-61-22].

Remove the coupler (Item 2) [Figure 20-61-22] from the hydraulic pump shaft.

Reverse the removal procedure to install the hydraulic pump.

Installation: Use a new O-ring (Item 1) [Figure 20-61-22] when installing the hydraulic pump.