If the standard size bearing cannot be employed due to excessive wear of the crankpin and crank journal use undersize or oversize bearings.

For undersize or oversize bearing use, follow the precautions noted below.

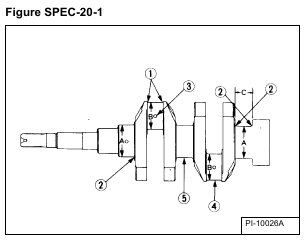

Grind the crankpin and journal with a wheel which has specified round corner and width without shoulder [Figure SPEC-20-1].

1. 0.1299-0.1457 in. Radius (3,3-3,7 mm Radius)

2. 0.1102-0.1260 in. Radius (2,8-3,2 mm Radius)

3. Be sure to chamfer the oil hole circumference to 0.0394-0.0591in. Radius (1,0-1,5 mm Radius) with an oil stone.

4. The crankpin must be fine finished to higher than (0.000016in.-S).

5. The crank journal must be fine-finished to higher than (0.000016in.-S).

6. The crank journal side surface must be fine-finished to higher than (0.000016in.-S).