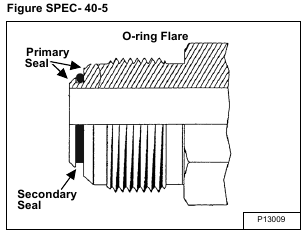

The flare is the primary seal, the O-ring is the secondary seal and helps absorb vibration and pressure pulses at the connection [Figure SPEC- 40-5].

If necessary, the O-ring-flare fitting can be used without an O-ring.

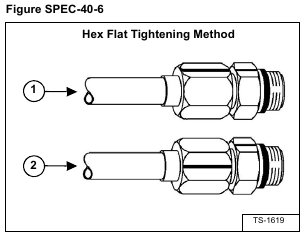

Use the following procedure to tighten the O-ring flare fitting.

Tighten the nut until it contacts with the seat. Make a mark across the flats of both the male and female parts of the connection (Item 1) [Figure SPEC-40-6].

Use the chart below to find the correct tightness needed (Item 2) [Figure SPEC-40-6]. If the fitting leaks after tightening, disconnect it and inspect the seat area for damage.

NOTE: O-ring flare fittings are not recommended in all applications. Use the standard flare fittings in these applications.

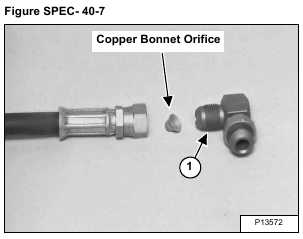

Do not use a O-ring flare fitting when a copper bonnet orifice is used. When tightened the connection at the bonnet may distort the flare face and prevent it from sealing.

Use a standard flare fitting (Item 1) [Figure SPEC- 40-7] as shown.

When a O-ring flare fitting is used as a straight thread port adapter the O-ring flare face is not used to seal. The O-ring may come off the fitting and enter the system.

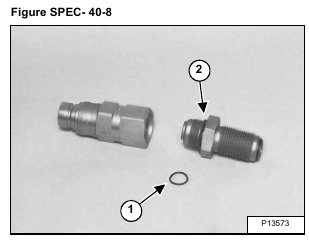

Always remove the O-ring (Item 1) from the flare face as shown.[Figure SPEC- 40-8]

An O-ring (Item 2) [Figure SPEC- 40-8] is added to the flat boss of the fitting to seal the connection in this application.