The tools listed will be needed to do the following procedure:

MEL1563 – Remote Start Tool

MEL10003 – Hydraulic Tester

MEL10006 – Hydraulic Test Kit

Lift and block the loader. (See LIFTING AND BLOCKING THE LOADER on Page 10-10-1.)

Raise the lift arms and install an approved lift arm support device. (See Installing Lift Arm Support Device on Page 10-20-1.)

Raise the operator cab. (See Raising The Operator Cab on Page 10-30-1.)

Open the rear door of the loader.

Connect the remote start switch. (See REMOTE START on Page 10-60-1.)

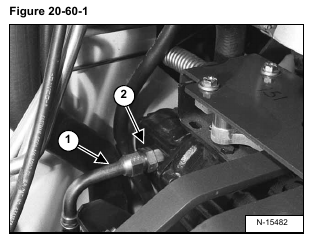

Disconnect the OUTLET hose (Item 1) from the OUTLET fitting (Item 2) [Figure 20-60-1] on the pump.

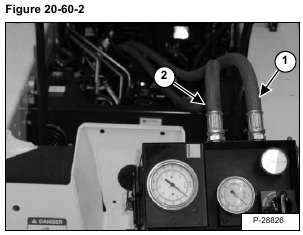

Connect the INLET hose (Item 1) [Figure 20-60-2] from the tester to the OUTLET fitting (Item 2) [Figure 20-60-1]

of the pump. Connect the OUTLET hose (Item 2) [Figure 20-60-2] from the tester to the hose (Item 1) [Figure 20-

60-1] which was disconnected from the pump.

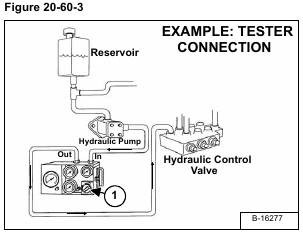

Sample tester connection shown [Figure 20-60-3].

Start the engine and run at low idle RPM. Make sure the tester is connected correctly. If no flow is indicated on the

tester, the hoses are connected wrong. With the hoses connected correctly, increase the engine speed to full RPM*.

Warm the fluid to 140°F. (60°C.) by turning the restrictor control (Item 1) [Figure 20-60-3] on the tester to about

1000 PSI (6895 kPa). DO NOT exceed system relief pressure. Open the restrictor control and record the free flow (GPM) at full RPM.

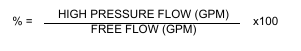

Push the maximum/variable flow switch (on the remote start tool) to engage the front auxiliary hydraulics, the

light will come ON. Push the button (on the right steering lever) for fluid flow to the quick coupler (fluid pressure will go over main relief). Record the highest pressure (PSI) and flow (GPM). The high pressure flow must be at least

80% of free flow.

A low percentage may indicate a failed pump.

*Refer to SPECIFICATIONS Section SPEC-01 for system relief pressure and full RPM.