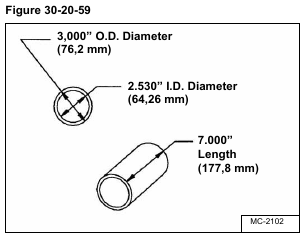

It is necessary to locate or fabricate a press tool for this procedure. Refer to photo [Figure 30-20-59] for the

correct dimensions of the tool needed.

A hydraulic press, slide hammer with puller end and snap ring pliers are also recommended for this procedure.

Remove the motor carrier shaft seal. (Refer to Disassembly on Page 30-20-4)

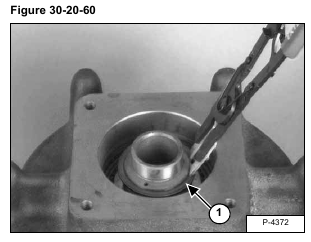

Remove the snap ring (Item 1) [Figure 30-20-60] from the motor carrier shaft using the snap ring pliers.

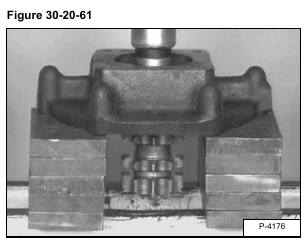

Put the motor carrier in the hydraulic press as shown [Figure 30-20-61].

Use 2-1/4 inch driver tool and press the sprocket shaft out of the motor carrier housing [Figure 30-20-61].

NOTE: The outer bearing will now be free from the sprocket shaft.

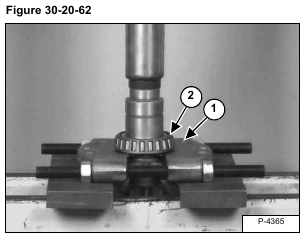

Remove the housing from the press and install a bearing puller (Item 1) [Figure 30-20-62] on the sprocket shaft.

Put the assembly in the hydraulic press. Use the same tool driver and remove the bearing (Item 2) [Figure 30-

20-62] from the shaft.

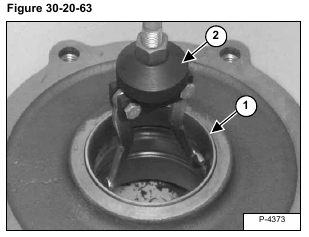

Fasten the carrier motor housing to the work surface securely with the inner bearing race (Item 1) [Figure 30-

20-63] facing up.

Install the slide hammer with puller end (Item 2) [Figure 30-20-63] on the bottom side of the bearing race.

Remove the bearing race from the carrier housing [Figure 30-20-63].

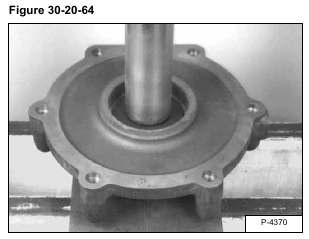

Put the motor carrier housing in the hydraulic press as shown [Figure 30-20-64].

Use a 3-7/8 inch driver tool and press the outer bearing race from the housing.

Check all parts for wear and damage. Replace the bearing race when new bearings are to be installed.