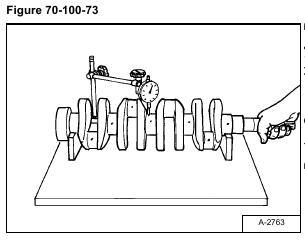

Put the crankshaft on V-blocks. Install a dial indicator on the center journal [Figure 70-100-73].

Turn the crankshaft at a slow rate.

If the misalignment exceeds the allowable limit, replace the crankshaft.

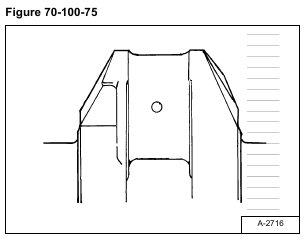

Measure the crankpin O.D.[Figure 70-100-75].

Calculate the oil clearance.

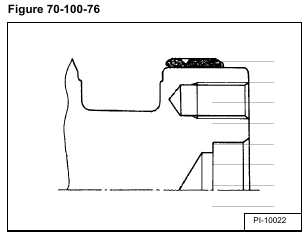

Check the wear on the crankshaft sleeve [Figure 70-100-76].

If the wear exceeds the allowable limit or the seal leaks oil, replace the sleeve.

The special tool set (Kubota Code Number: 07916-32091) will be needed to replace the crankshaft sleeve.

Remove the sleeve.

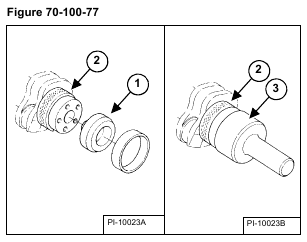

Install the sleeve guide (Item 1) and stop (Item 2) [Figure 70-100-77].

Heat the sleeve to about 300°F (150°C). install the sleeve on the crankshaft using the special driver tool (Item 3) [Figure 70-100-77].

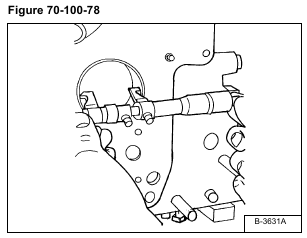

Measure the I.D. of the No.1 crankshaft bearing [Figure 70-100-78].

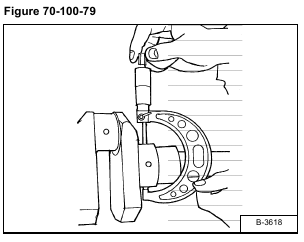

Measure the O.D. of the crankshaft journal [Figure 70-100-79].

Calculate the clearance.

If the clearance exceeds the allowable limit, replace the crankshaft bearing.

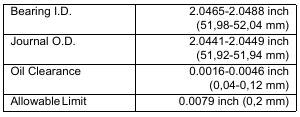

To remove the front bearing make the driver tool as shown in figure [Figure 70-100-80].

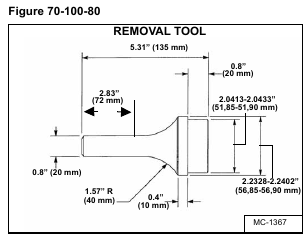

To install the front bearing make the driver tool as shown in [Figure 70-100-81]

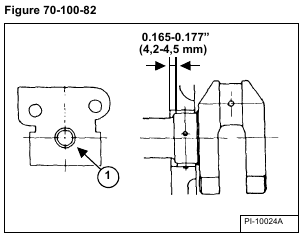

Remove the front bearing (Item 1) [Figure 70-100-82] with the special removal tool.

Installation: Clean the new bearing and bore, apply oil on them. Install the new bearing with the installation driver tool [Figure 70-100-82].

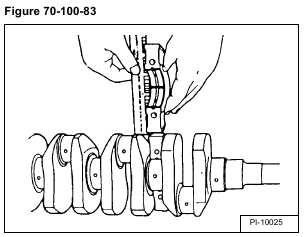

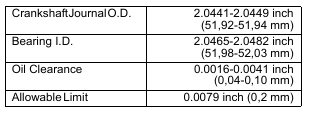

Clean the crankshaft journal and bearing. Put a strip of press gauge on the center journal.

Install the main bearing case halves and tighten the bolts.

Remove the bearing case halves.

Measure the flattened press gauge [Figure 70-100-83].

If the clearance exceeds the allowable limit, replace the crankshaft bearing.