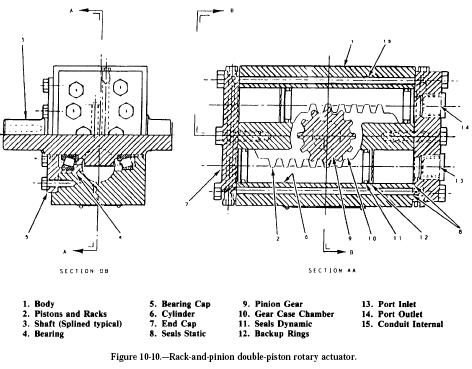

referred to as limited rotation cylinders, of the single or multiple, bidirectional piston are used for turning, positioning, steering, opening and closing, swinging, or any other mechanical function involving restricted rotation. Figure 10-10 shows a typical rack-and-pinion double piston actuator.

The actuator consists of a body and two reciprocating pistons with an integral rack for rotating the shaft mounted in roller or journal bearings. The shaft and bearings are located in a central position and are enclosed with a bearing cap. The pistons, one on each side of the rack, are enclosed in cylinders machined or sleeved into the body. The body is enclosed with end caps and static seals to prevent external leakage of pressurized fluid.

Only a few of the many applications of actuating cylinders were discussed in the preceding paragraphs. Figure 10-11 shows additional types of force and motion applications.

In addition to its versatility, the cylinder-type actuator is probably the most trouble-free component of fluid power systems. However, it is very important that the cylinder, mechanical linkage, and actuating unit are correctly aligned. Any misalignment will cause excessive wear of the piston, piston rod, and seals. Also, proper adjustment between the piston rod and the actuating unit must be maintained.