Clean all parts in solvent and dry with compressed air.

Inspect the cylinder parts for wear or damage. Replace any damaged parts.

Always install new O-rings and seals during assembly.

Lubricate all O-rings and seals with hydraulic oil during installation.

Use the following tools to assemble the cylinder:

MEL1396 – Universal Seal Expander

MEL1033 – Rod Seal Installation Tool

MEL1396-2 – Piston Ring Compressor

MEL1075 – Adjustable Gland Nut Wrench

MEL1075-2 – Special Offset Pins

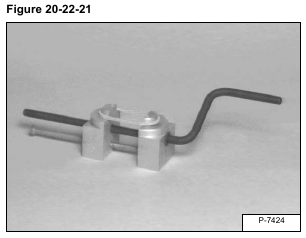

Install the new seal on the tool and slowly stretch it until it fits the piston [Figure 20-22-21].

Allow the seal to stretch for 30 seconds before installing it on the piston.

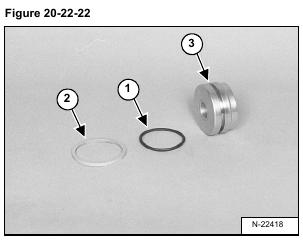

Install the O-ring (Item 1) and seal (Item 2) on the piston (Item 3) [Figure 20-22-22].

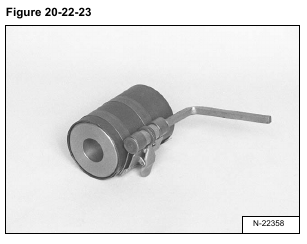

Use a ring compressor to compress the seal to the correct size. Leave the piston in the compressor for approximately three minutes [Figure 20-22-23].

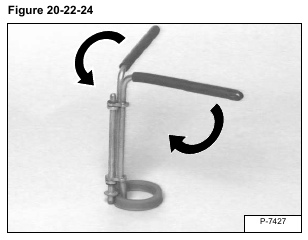

Install the rod seal on the rod seal tool [Figure 20-22-24].

NOTE: During installation the spring side of the seal must be toward the inside of the cylinder.

Rotate the handles to collapse the rod seal [Figure 20-22-24].

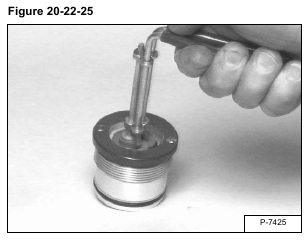

Install the rod seal in the head [Figure 20-22-25].

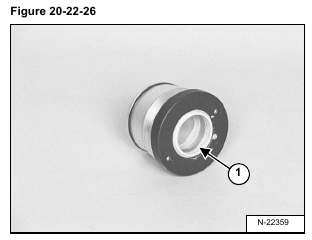

Install the wiper seal with the wiper (Item 1) [Figure 20-22-26] toward the outside of the head.

Install the wear ring (Item 1) [Figure 20-22-27].

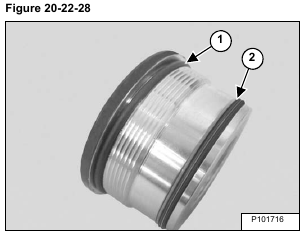

Install the O-ring (Item 1) [Figure 20-22-28].

Install the seal (Item 2) [Figure 20-22-28].

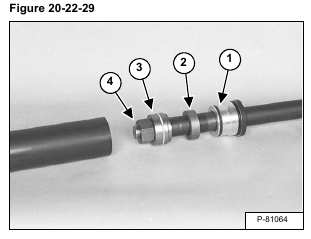

Install the head (Item 1), spacer (Item 2) and the piston (Item 3) [Figure 20-22-29] on the rod.

Grease the piston where the nut contacts the piston. Do not get grease on the threads.

Provide an adequate support for the cylinder before tightening.

NOTE: Clean and dry the rod threads. Install a NEW NUT with pre-applied Loctite®.

Install the nut (Item 4) [Figure 20-22-29].

Tighten the nut to 1491 N•m (1100 ft-lb) torque.

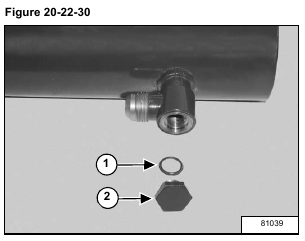

Install the O-ring (Item 1) and plug (Item 2) [Figure 20-22-30].

Tighten the plug to 50 N•m (37 ft-lb) torque.

Put the base end of the cylinder in a vise.

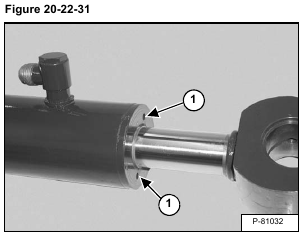

Insert the adjustable gland nut wrench into the holes (Item 1) [Figure 20-22-31] to tighten the head. Tighten the head until it is flush with the end of the housing.

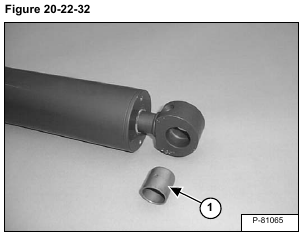

Install the bushing (Item 1) [Figure 20-22-32]. Make sure the bushing is aligned with the grease channel in the cylinder.