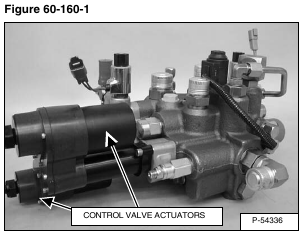

[Figure 60-160-1] Excessive actuator loading can occur if the actuator and valve spool components are misaligned. Misalignment may reduce spool stroke performance and reduce the life of the actuator. Starting with software version 36, the Bobcat Service Analyzer will be able to perform tests to diagnose actuator and valve spool misalignment.

Connect the Service PC (See SERVICE PC (LAPTOP COMPUTER) on Page 60-150-1.)

If a Service PC is not available, (See Lift And Tilt Calibration (SJC) on Page 60-160-5.) or (See Lift And Tilt Calibration (ACS) on Page 60-160-3.).

NOTE: Warm the hydraulic oil to room temperature 72° F (22° C), stop the engine and clear all active service codes before running the test.

Once the test is initiated, an automatic calibration sequence will start. When calibration is complete, the test will be performed and the results can be viewed on the Service PC (Laptop) monitor.

This test will engage both actuators to fully stroke the spools then allow the centering springs to return the spools to neutral. Next, both actuators are engaged to move the spools just past the neutral points then allow the centering springs to return the spools to neutral.

When complete, the Actuator Test will show a pass mode or fail mode. The pass mode indicates that no problems were detected. The fail mode indicates one or a combination of three problems below.

• Actuator slow return to neutral. The spool returns to neutral too slowly.

• Actuator did not fully extend/retract. During the test, the spool was not able to fully stroke in both directions.

• Actuator out of neutral. The spool did not return to the neutral window during the test.

NOTE: A time out will occur if the test cannot be completed within 8 seconds. If this happens, retry the test.

[Figure 60-160-2] If the initial Actuator Test results in a fail mode due to a slow return to neutral, follow the troubleshooting tree to pinpoint the probable cause.

If the Actuator Test fails after the hydraulic oil is warmed, go to the next step and loosen the bolts that mount the actuator to the control valve. Loosen the bolts just enough so the actuator can be moved slightly up / down or side / side.

Rerun the Actuator Test, if the test passes, check the following probable causes in Column 1 [Figure 60-160-2]. Check the probable causes in the order they are listed. Repairing one cause may be all that is required. Re-run the test to verify.

NOTE: Actuator and spool misalignment. Re-tighten the two bolts evenly, turn the first bolt one turn, then turn the other bolt one turn until both bolts are tight.

The pin may be too large. Oversized pins exceeding 0.248 in. (6,30 mm) in diameter should be replaced.

If the Actuator Test failed due to a slow return to neutral after checking the probable causes in Column 1 [Figure 60-160-2], check the following probable causes in Column 2 [Figure 60-160-2].

• Contamination in the spool.

• The spool end cap may be defective or the centering spring may be broken. Inspect the end cap and the centering spring, replace if necessary.

• The wire harness or connectors may have an intermittent short. Check the connections and wire harnesses.

• The controller may be defective, replace the controller.

If the initial Actuator Test results in the fail mode actuator did not fully extend / retract, check the following.

• The actuator connectors may be reversed between the lift and tilt actuator. Reverse the connectors and rerun the Actuator Test.

• The actuator may be weak, replace the actuator.

• The spool end cap may be defective or the centering spring may be broken. Inspect the end cap and the centering spring, replace if necessary.

• Contamination in the spool.

If the initial Actuator Test results in the fail mode actuator out of neutral, check the following.

• The actuator may be defective, replace the actuator.

• The spool end cap may be defective or the centering spring may be broken. Inspect the end cap and the centering spring, replace if necessary.

• Contamination in the spool.