The controller uses a calibration sequence to optimize the control system. The optimizing ensures full spool stroke (full flow) while preventing over stroke (loading) of the actuator and resets the calibration points in the controller.

NOTE: The Actuator Test is the preferred method to calibrate the lift and tilt actuator. (See Actuator Testing on Page 60-160-1.)

NOTE: This calibration procedure must be followed when replacing a hydraulic control valve, actuator or ACS controller. Failure to calibrate after component replacement may result in poor performance or reduced life of actuator(s).

Update the loader service software to the latest version.

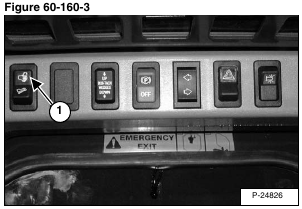

Place the rocker switch (Item 1) [Figure 60-160-3] in the hand control mode.

Close the cab door. (If loader is equipped.)

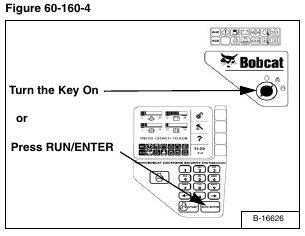

With the seat bar down, turn the ignition key ON (keyless panel press RUN/ENTER) [Figure 60-160-4].

NOTE: Do not start the engine.

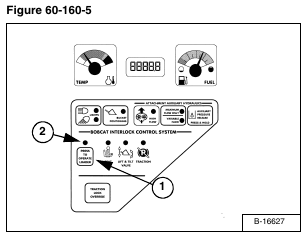

Push the PRESS TO OPERATE button (Item 1) [Figure 60-160-5] to unlock the hand controls.

Fully stroke both control handles in toward the center of the cab and hold the handles [Figure 60-160-6].

Lift the seat bar, high enough for the PRESS TO OPERATE light (Item 2) [Figure 60-160-5] to go OFF.

Lower the seat bar.

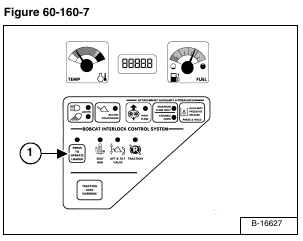

Push the PRESS TO OPERATE button (Item 1) [Figure 60-160-7] to begin calibration.

NOTE: The ACS icon will light up and if you listen closely the cycling of the actuators can be heard. The ACS icon will stay lit until the ignition key is cycled or the loader is started and a function is operated.

NOTE: During the calibration cycle, the system will beep three times. Once the calibration is complete code 32-24 (Calibration Performed) will be generated.

Release the control han dles.

Calibration is complete.