Timing the injection pump is done by changing the number of shims between the injection pump and the injection pump mounting surface.

Disconnect the number one (closest to water pump) cylinder high pressure line from the injection pump.

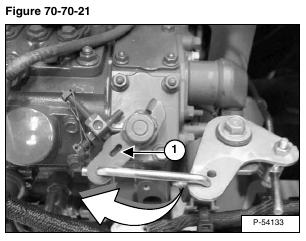

Turn the fuel supply lever (Item 1) [Figure 70-70-21] to the ON position.

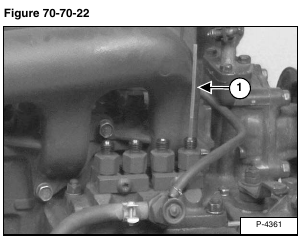

Install a short plastic tube (Item 1) [Figure 70-70-22] in the number one cylinder port of the injection pump. The tube should fit securely in the port and point upward.

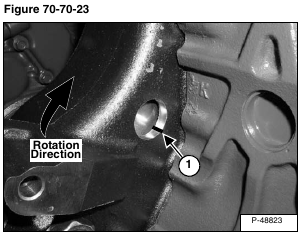

Rotate the engine in the direction shown [Figure 70-70-23].

Continue rotation until flywheel timing mark just appears in the window (Item 1) [Figure 70-70-23].

NOTE: The flywheel has three timing marks.

The first mark to appear in the window with the rotation is 9.25° which is used for loaders with the Kubota V2003T engine.

The second mark to appear in the window is 8.2° which is used for loaders with the Kubota V2203 engine.

The third mark to appear in the window is 6.75° which is used for loaders with the Kubota V2403 engine.

Rotate slowly until fuel just starts to flow upward into the plastic tube.

At this instant, the 9.25 ° BTDC timing mark on the flywheel should be aligned with the mark in the window (Item 1) [Figure 70-70-23] for the V2003T engine.

OR

The 8.2° BTDC on the flywheel should be aligned with the mark in the window (Item 1) [Figure 70-70-23] for the V2203 engine.

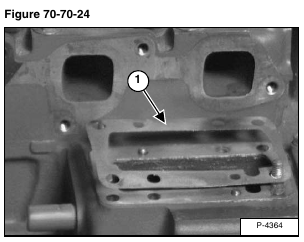

Add or subtract shim(s) (Item 1) [Figure 70-70-24] as needed to adjust the fuel delivery timing.

NOTE: Adding or removing one shim will vary the timing by 1.5°. Adding shims retards timing.

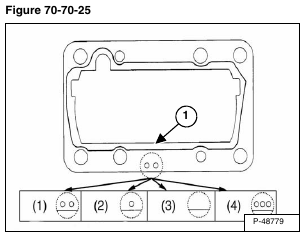

The size of shims are identified by a symbol on the shims.

(1) Two holes means 0.008 in (0.20 mm) shim.

(2) One hole means 0.010 in (0.25 mm) shim.

(3) Without hole means 0.012 in (0.30 mm) shim.

(4) Three holes means 0.014 in (0.35 mm) shim.