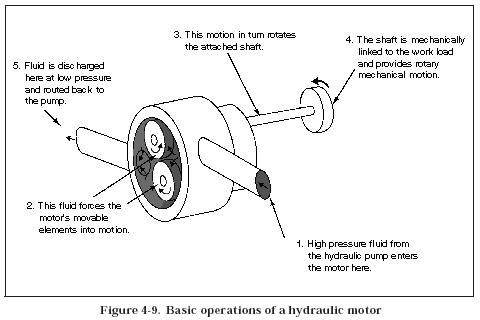

Hydraulic motors convert hydraulic energy into mechanical energy. In industrial hydraulic circuits, pumps and motors are normally combined with a proper valving and piping to form a hydraulic-powered transmission. A pump, which is mechanically linked to a prime mover, draws fluid from a reservoir and forces it to a motor. A motor, which is mechanically linked to the workload, is actuated by this flow so that motion or torque, or both, are conveyed to the work. Figure 4-9 shows the basic operations of a hydraulic motor.

The principal ratings of a motor are torque, pressure, and displacement. Torque and pressure ratings indicate how much load a motor can handle. Displacement indicates how much flow is required for a specified drive speed and is expressed in cubic inches per revolutions, the same as pump displacement. Displacement is the amount of oil that must be pumped into a motor to turn it one revolution. Most motors are fixed-displacement; however, variable- displacement piston motors are in use, mainly in hydrostatic drives. The main types of motors are gear, vane, and piston. They can be unidirectional or reversible. (Most motors designed for mobile equipment are reversible.)