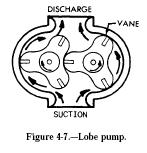

The lobe operation as pump uses the same principle of the external gear pump described previously. The lobes are considerably larger than gear teeth, but there are only two or three lobes on each rotor. A three-lobe pump is illustrated in figure 4-7. The two elements are rotated, one directly driven by the source of power, and the other through timing gears. As the elements rotate, liquid is trapped between two lobes of each rotor and the walls of the pump chamber and arried around from the suction side to the discharge side of the pump. As liquid leaves the suction chamber, the pressure in the suction chamber is lowered, and additional liquid is forced into the chamber from the reservoir.

The lobes are constructed so there is a continuous seal at the points where they meet at the center of the pump. The lobes of the pump illustrated in figure 4-7 are fitted with small vanes at the outer edge to improve the seal of the pump. Although these vanes are mechanically held in their slots, they are, to some extent, free to move outward. Centrifugal force keeps the vanes snug against the chamber and the other rotating members.